SOLAR DRYER DOME, SIMPLE TECHNOLOGY APPLICATION FOR SEAWEED FARMERS

Author: Nur Ahyani (Aquaculture Officer, WWF-Indonesia)

Seaweed farmers, everywhere including Alor, have always relied on the heat energy of the sun to dry seaweed. Immediately after harvesting, they dry their seaweed, either on drying beds or on stones that have been arranged in such a way. They also have to turn the seaweed over periodically to allow it to dry completely. If the sun is shining well, it takes approximately three days before the seaweed can be packaged and sold.

The Solar Dryer Dome technology has been introduced in Alor by the Asia Society for Social Improvement and Sustainable Transformation (ASSIST) supported by COVESTRO. Through the WeCare program, this new technology is being introduced to farmers with the aim of improving the quality of seaweed to increase its market value. In line with the aims of WeCare,WWF-Indonesia is committed to assisting this organization in carrying out its activities in Alor. Facilitated by the Alor Seaweed Forum (FoRLa) and WWF-Indonesia, field visits to four communities in Alor were carried out in February 2016. After a key study was conducted in the villages of Aimoli, Bana, Kayang, and West Kalondama, and considering transportation issues as well as the interest of the local communities, it was decided to build the solar dryer dome in Aimoli village.

Silpakorn University, Thailand developed the Solar Dryer Dome technology using the same principle as conventional seaweed drying - utilizing the sun as an energy source. The Solar Dryer Dome is built using a parabolic roof structure that resembles a dome and maximizes heat circulation within the building. Sunlight will penetrate into the polycarbonate sheets and heat the air inside the dome. The hot air then absorbs moisture from the products being dried. The air is then sucked in by a fan attached to the dome. Typically, drying seaweed in the sun normally takes three days, but drying in the dome can be cut in half.

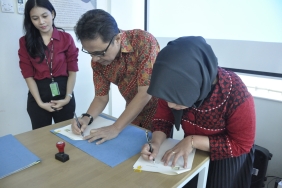

began construction in Aimoli Village on May 26, 2016. Workers and farmer groups helped, and on May 29, 2016 they completed the dome. The day after, FoRLa-Alor invited seaweed farmers to attend a socialization about the Solar Dryer Dome. Somwang Martchaipoom, an expert representative from Silpakorn University, explained how the dome works; the benefits of using a solar dryer dome; and how to maintain it. In his explanation, he said that not only is the drying period shorter, the seaweed produced is cleaner and has less weight loss. Somwang also emphasized that people can use the solar dryer dome for at least 15 years under normal conditions. If the community takes good care of the drying dome, it is possible that the usage period will increase to 20 years. Maintenance is quite easy and inexpensive, by periodically cleaning the solar panels and polycarbonate sheets from dust and drying residue salts.

In addition, the farmers were also asked to practice seaweed drying experiments, using the Solar Dryer Dome or conventional methods. With temperatures that can reach 50 degrees Celsius in the Solar Dryer Dome, of course the drying process can be more effective and efficient. Seeing the enthusiasm of the community during the socialization, WWF-Indonesia as a facilitator certainly hopes that they can use it well and get the maximum benefit from the application of the technology.